Silca now offers 3D printed, titanium cleats

The usual SPD cleats that we've come to know and love are usually made from softer metals in order to make sure that the cleat wore faster than the pedal interface. More often than not, this means that we're left with heavy cleats that wear super quickly. That is until now, as Silca has announced a new, 3D printed titanium cleat.

- The best clipless mountain bike pedals ridden and rated

- When should I replace my mountain bike pedal cleats?

To create the new cleats, Silca has used 6/4 titanium that claimed to only be ever so slightly softer than a pedal's interface. It's also said to be 2.25x stronger and 3x harder than the usual brass of mild steel cleats. That means that the overall toughness and abrasion resistance of the new titanium cleat is promised to offer 300-400% wear life compared to traditionally made cleats.

It's not just Silca's choice of titanium that makes the new cleats special, however, it's also the fact that they are 3D printed. 3D printing the cleats has allowed Silica to build them with an internal lattice structure, usually called a gyroid, which retains stiffness and strength but further reduces the weight of the cleat to around half the weight of a traditionally made cleat set, says the brand.

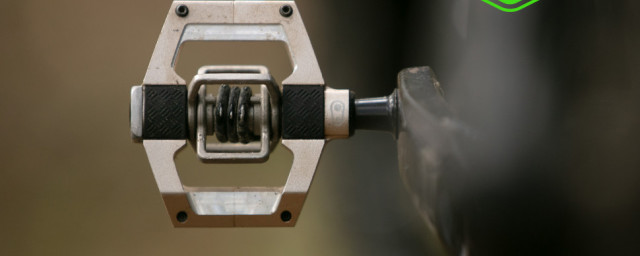

Silca's new titanium cleats include CNC machined washer plates, 6/4 titanium mounting screws with T25 tool interfaces. They're also available with Shimano SPD, Crankbrothers, and Time ATAC compatibility.

As for price, that's $85 (around £63) for a pair.

Comments

Shiny!

What a stupid idea. Take a £12 item and make a £63 version that will wear out your expensive pedals much faster.

Titanium 3D printing really does seem to be the new fad for the stupid with more cash than brain cells.

its clear form the article that the aim is still to have softer cleats than pedals, so will be interesting to see if their prototyping and testing work out in the real world. As an appraoch to material engineering this makes sense and having longer lasting products is good for reducing waste , as is using less material in more up to date ways. Will be intersting to see if this translate to road cleats too with huge amounts of plastic compared to the wearing parts.

£16 is the cheapest at the mo...times 4 (roughly what they claim the new cleats will last compared to standard) and you have spent £64, possibly plus x4 postage.

And not forgetting the environmental costs of 4 sets of disposable cleats being made and transported. So it may make some sense if they work as advetised.

And they are softer than the pedal as it said in the article.

From a road pedal user: You have NO problems with fast wear.

Ive probably been wearing the same Shimano SH-56 cleats since 2016 - Still clip in and out just fine.

Plenty of more miles left on them id say

Take a none existant problem and make it exclusive. Rubbish marketing and excution. Stronger than hardened steel? so lies also

This is ridiculous! As someone whole deals with 3D printing on a daily basis (admittedly plastic but similar principals apply) there is zero benefit to 3D printing a commodity part. The advantags of 3D printing come from it's ability to cheaply produce single or low volume run copies of an object, not in it's superiority strength wise (quite the opposite in fact).

The worst part is most titanium 3D printing is done on a layer by layer basis using a laser to build up the part. The gyroid infill suggests they are doing exactly this. That means that there will be very small ridges between each layer where they are bonded. The cleat will likely act as a very fine file as it moves around INCREASING the wear on your pedals! Maybe that's it, it last 400% longer because the pedal now fails first

A completely daft idea but it got them some publicity which was no doubt the point. I've only ever used spd and in the last twenty plus years have replaced two or three sets of cleats. They go on and on and on and on and on, why you'd buy a pair if these is beyond me.

I think I replaced my last ATAC cleats after 30 years or so ?